MBM AeroCut Velocity Complete Air Feed Paper Digital Finisher

MBM AeroCut Velocity Complete Air Feed Paper Digital Finisher is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Spec Sheet: View PDF File

User Manual: View PDF File

Product Specifications

| Product Name | MBM AeroCut Velocity Complete Air Feed Paper Digital Finisher |

| Manufacturer | MBM |

| SKU | CU0485P |

| Sheet Capacity | 4" |

| Speed (sheet/min) | 20 |

| Dimensions (H”xW”xD”) | 42 x 75.35 x 28 |

| Paper Size (W" x L") | 8.25 x 8.25 to 14.5 x 47+ |

| Paper Weight (Gsm) | 120 - 400 gsm |

| Power Supply (Volts) | 115V |

| Tri-Suction Feeding Mechanism | Yes |

| Applications | business cards, post cards, invitations, greeting cards, leaflets, tickets and more. |

| Flex Mode | Yes |

| Warranty | 1 year limited warranty |

| Included Software | Lytrod Intellicut software |

| Optional Accessories | Perforator (AC0446), Barcode reader (AC0423) |

Product Description:

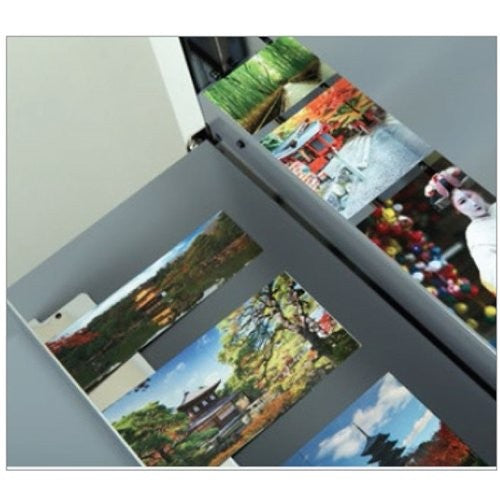

Features of the MBM AeroCut Velocity Complete Air Feed Paper Digital Finisher

- Features 150 save able custom programs 263 preset cutting jobs

- Operating speed of 20 sheets in a minute and 1200 in an hour

- Interactive and intuitive touch screen panel for easy and simple use

- Inclusive of Lytrod Vision Direct software for simple and accurate operations

- Flex mode caters to cut multiple size cards and add desired numbers of creases

- Patented tri-suction feed system mechanism decreases misfeeding or double feed

- Self sharpening blades allows machine to trim approximately 400 gsm without wear

- Finishes applications like business cards, post cards, invitations, tickets etc.

- Easy maintenance with detachable rollers preventing paper jams

- Self-correcting cut mark operation for accurate cuts every time

- Two single and double blade slitters for precise cutting and center gutters

- Vision Direct software promotes efficient cutting with fast and simple procedure

- Includes perforator and barcode reader for additional functioning

MBM has constructed durable and efficient AeroCut Velocity digital finisher that is an ideal addition to your workplace as it covers up features like cutter, creaser , slitter, perforator and as well as barcode reader. This machine is a heavy duty machine as its constructed with full metal body with variety of features of exclusive functioning. The digital finisher includes a creasing unit that can be adjusted in 5 levels, slitting and cutting units with 2 single and double blade slitters for accurate trimming and flex mode that allows to cut multiple sizes and add desired creases.

The MBM AeroCut Velocity digital finisher is a complete package which includes 263 preset cutting jobs and the ability to store 150 additional programs. With the tri-suction feeding mechanism there is almost no chance of double feed or misfeeding and it enhances productivity of the workplace with its flawless operations. The single and double self sharpening blades can cut up to 400 gsm without any wear. Vision Direct software promotes efficient cutting with fast and simple procedure like formatting, imposing, and adding personalized information etc. This extraordinary unit includes a perforator and barcode reader as well.

Warranty & RecommendationMBM AeroCut Velocity is constructed with an innovative technology making it an innovative product that assists workplace with various functions all in one place. To ensure customer satisfaction the cutter is backed with 1-year limited warranty excluding wearables.

Frequently Asked Questions

Q: For how long am i entitled to warranty?

A: The AeroCut Velocity digital finisher comes with a 1 year limited warranty excluding wearables.

Q: What creasing levels can be adjusted and how?

A: Creasing pressure can be adjusted in 5 levels instantly by shifting the lever.

Q: How does the Lytrod VisionDirect software assits with AeroCut Velocity?

A: The Lytrod VisionDirect software promotes efficient cutting and impose artwork + address data to seamlessly.

Q: What does the self correcting cut mark function do in the AeroCut Velocity?

A: Self-correcting cut mark registration function and air suction feed system ensure accurate cuts every time.